Wire mesh and filters are integral elements in many industries, prized for his or her longevity, adaptability, and precision. From filtration programs to structural reinforcements, resources like woven wire mesh, knitted wire mesh, cylinder filters, sintered mesh, and sintered wire mesh cater to an unlimited array of apps. This post explores their unique characteristics and crucial works by using.

Woven Wire Mesh: Precision and Power

Woven wire mesh consists of interlaced metallic wires, forming a really uniform grid with exact openings. Its higher tensile toughness and versatility allow it to be a staple in industries which include development, agriculture, and mining. Obtainable in numerous weave styles, like simple, twill, and Dutch weave, woven wire mesh is engineered to satisfy specific performance demands. Typical apps contain sieving, filtration, and building protective limitations, as well as structural assist in numerous tasks.

Knitted Wire Mesh: Overall flexibility and Flexibility

As opposed to the rigid composition of woven mesh, knitted wire mesh attributes interlocking loops of wire, offering it extraordinary flexibility. This adaptability makes it ideal for apps demanding compressible and expandable products. Often Utilized in mist eliminators, knitted wire mesh improves effectiveness in industrial fuel and liquid processing. It is also beneficial in shielding in opposition to electromagnetic interference (EMI) and as vibration-damping parts in automotive exhaust units.

Cylinder Filters: Compact and Effective

Cylinder filters are tubular filtration options crafted from wire mesh or sintered components. Their Knitted Wire Mesh cylindrical layout permits large circulation costs even though successfully taking away undesired particles. Industries like oil refining, drinking water treatment method, and chemical processing depend upon these filters for compact nevertheless effective functionality. Their resistance to strain and corrosion, coupled without difficulty of installation, makes them a preferred option for demanding filtration duties.

Sintered Mesh: Constructed for Intense Circumstances

Sintered mesh is established by layering various sheets of wire mesh and fusing them by way of a sintering method involving heat and tension. This process results in a rigid, porous composition that excels in mechanical energy and thermal resistance. Sintered mesh is commonly Utilized in large-temperature and high-force environments, including industrial filtration units, automotive catalytic converters, and processes demanding precise separation of solids and liquids.

Sintered Wire Mesh: Multi-Layered Precision

Comparable to sintered mesh, sintered wire mesh combines quite a few layers of woven wire mesh to accomplish enhanced toughness and filtration accuracy. Its multi-layered development ensures uniformity and great backwash efficiency, which makes it an ideal choice for industries that Sintered Wire Mesh demand from customers robust filtration devices. Sintered wire mesh is especially handy in applications necessitating resistance to deformation less than hefty masses and extensive-phrase effectiveness in severe situations.

Conclusion

The flexibility and trustworthiness of wire mesh and filters—like woven wire mesh, knitted wire mesh, cylinder filters, sintered mesh, and sintered wire mesh—have designed them indispensable throughout industries. No matter whether employed for filtration, shielding, or structural reinforcement, these materials are engineered to deliver Excellent effectiveness. Their adaptability and resilience be certain they remain a cornerstone of industrial innovation, catering towards the ever-evolving demands of contemporary technological know-how and producing.

Alana "Honey Boo Boo" Thompson Then & Now!

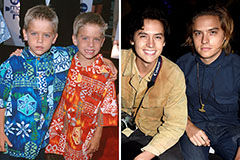

Alana "Honey Boo Boo" Thompson Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!